In industrial manufacturing, the demand for efficient and reliable crushing equipment has never been higher. One of the most crucial tools in this domain is the powerful crusher, which utilizes mechanical force to reduce materials into smaller particles. Our article explores the working principles, core components, and applications of powerful crushers, helping you determine which type might best suit your needs.

The core components of a powerful crusher are the cutter and the motor. The motor drives the cutter at high speed, creating a powerful rotational force. When materials enter the crushing chamber, they encounter the high-speed rotating cutter, which exerts a strong impact force, breaking down larger pieces into smaller fragments.

However, the crushing process doesn’t stop there. The intense friction and shearing forces generated between the materials and the chamber walls further refine the fragments, transforming them into smaller particles or even fine powders that meet specific requirements. This dual-action mechanism ensures that the crushing process is thorough and efficient.

Several types of crushers are designed for different applications, each with its unique advantages. Here's a closer look at some common types:

A PVC crushing particle crusher is tailored for processing PVC materials, commonly used in industries producing plastic pipes, sheets, and films. Its design allows it to handle tough, resilient plastics, breaking them down into uniform particles suitable for recycling or further manufacturing.

Plastic Pellet Crusher

For industries dealing with plastic resins and pellets, the plastic pellet crusher offers unmatched precision. This type of crusher is particularly adept at reducing pre-formed plastic pellets into smaller granules or powders, which can then be used in the production of new plastic products.

When dealing with materials like minerals, metals, or other hard substances, an industrial pulverizer might be your best choice. These machines specialize in ultra-fine crushing, ideal for applications requiring a high level of refinement, such as in the pharmaceutical or chemical industries.

To select the most suitable crusher, it’s essential to understand the features that set a powerful crusher apart from less effective alternatives:

· High-Speed Motor: The motor’s speed and power directly affect the crushing efficiency. Higher speeds enable quicker and more thorough material processing.

· Durable Cutter Blades: The cutter's material and sharpness are critical. Blades made from high-strength alloys ensure longevity and the ability to handle various material types.

· Versatile Crushing Chamber: A well-designed crushing chamber ensures even distribution of material, optimizing the impact, friction, and shearing processes.

· Adjustable Output Size: Some crushers allow users to control the output size, making them versatile for different production requirements.

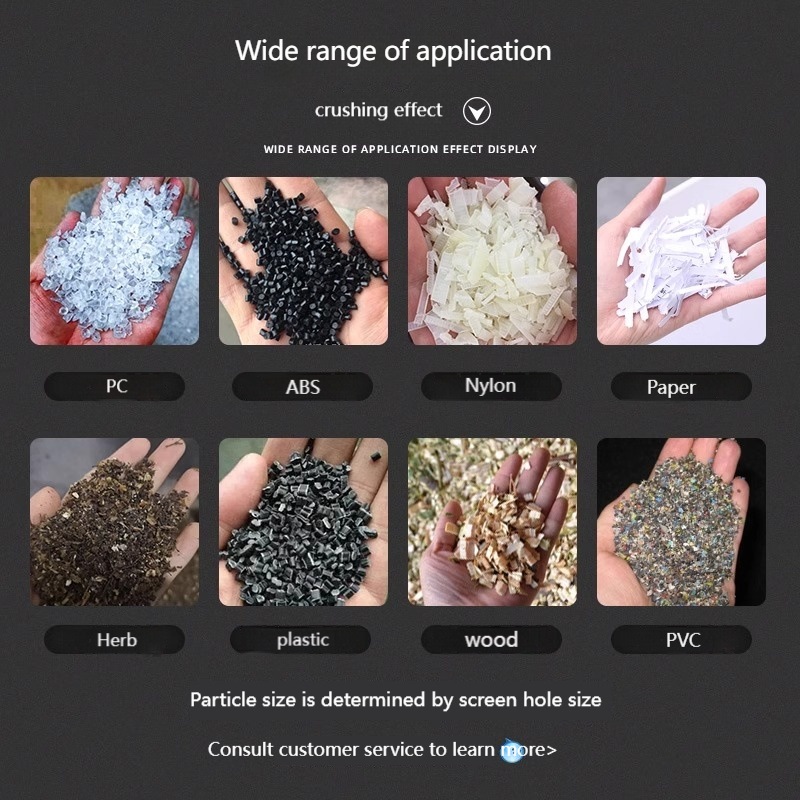

Powerful crushers find applications across a wide array of industries. Here are some notable examples:

· Plastic Recycling: Reducing plastic waste into reusable pellets or powder, aiding in the creation of sustainable manufacturing cycles.

· Pharmaceuticals: Crushing active ingredients into fine powders, ensuring accurate dosing in medication production.

· Food Processing: Pulverizing grains, spices, and other food materials to achieve the desired texture or consistency.

· Construction Materials: Breaking down rocks and concrete for use in new construction projects or recycling.

To ensure the longevity and optimal performance of your powerful crusher, regular maintenance is essential:

· Routine Inspection: Check the motor, blades, and crushing chamber for wear and tear.

· Proper Lubrication: Keep moving parts well-lubricated to minimize friction and prevent overheating.

· Clean the Crushing Chamber: After each use, clean the chamber to prevent material buildup, which could affect performance and hygiene.

· Blade Sharpening or Replacement: Dull blades reduce crushing efficiency and increase energy consumption. Regularly sharpen or replace them as needed.

Choosing the right crusher depends on the specific materials you work with and the desired output. Whether you need a PVC crushing particle crusher for plastic recycling, a plastic pellet crusher for precision in manufacturing, or an industrial pulverizer for fine grinding, understanding the mechanics and applications of each type will help you make an informed decision.

Ultimately, a powerful crusher is an indispensable tool for many industries, offering efficiency, precision, and versatility. By investing in the right machine and maintaining it properly, you can ensure long-term, high-quality performance in your production processes.If you have any purchasing needs for crushers, please send your product requirements to our email address 2314609053@qq.com and we will contact you within 24 hours.