Efficient and intelligent suction machine: a powerful assistant for innovating material handling

In modern industrial production, efficient handling and precise delivery of materials are key links to ensure the smooth progress of the production process. Our efficient and intelligent suction machine came into being, bringing a revolution in material handling to many industries, whether in food processing, pharmaceuticals, chemical production, plastic manufacturing and other industries, it can show excellent performance and unparalleled advantages.

Excellent performance, efficient operation

Powerful suction

This suction machine is equipped with a high-performance vacuum pump system that can generate strong and stable suction. Whether it is powdery, granular or small pieces of material, it can be easily sucked up, effectively solving the problems of material residue and pipe clogging caused by insufficient suction of traditional manual feeding or ordinary suction equipment. For example, in the flour production workshop, it can quickly suck a large amount of flour from the storage tank into the processing equipment, ensuring the continuity of production and greatly improving production efficiency.

High speed and high precision

Its advanced pneumatic control system and optimized pipeline design enable the material to be transmitted at a high speed and uniform flow rate during the suction process, ensuring the stability and accuracy of material supply. In the pharmaceutical capsule filling process, the suction machine can accurately transport the powder to the filling equipment. The filling error of each capsule is extremely small, which meets the strict quality requirements of pharmaceutical production and avoids the phenomenon of unqualified products caused by uneven materials.

Intelligent control, convenient and worry-free

Automatic control

Adopting advanced programmable logic controller (PLC) as the core control unit, with intuitive human-machine interface (HMI), the suction process is fully automated. Users only need to set the suction parameters on the HMI, such as suction time, suction volume, discharge position, etc., and the suction machine can automatically complete the entire suction and discharge process according to the preset program. In the chemical raw material batching link, the operator does not need to stay by the equipment for manual adjustment at all times. The suction machine will accurately absorb various raw materials according to different formulas and put them into the reactor in sequence, which not only reduces the labor intensity, but also significantly improves the accuracy and production efficiency of batching.

Remote monitoring and fault diagnosis

It has remote communication function, which can realize remote monitoring and operation through the enterprise internal network or the Internet. No matter where the operator is, he can check the working status of the suction machine anytime and anywhere through mobile phones, computers and other terminal devices, including key data such as suction force, material flow, and running time. Once the equipment fails, the system will automatically issue an alarm message and display detailed fault codes and solutions on the remote monitoring interface to help maintenance personnel quickly locate and troubleshoot the fault, minimize downtime, and reduce production losses.

Wide application and flexible and changeable

Multi-material compatibility

The unique suction structure design and diversified suction pipe configuration enable it to adapt to a variety of materials with different characteristics. Whether it is corrosive chemical raw materials, fragile crystal particles, or viscous paste materials, they can be safely and efficiently sucked and delivered. In food additive manufacturers, the same suction machine can suck different types of food additives, such as flavors, pigments, preservatives, etc., in turn, and accurately add them to different stations of the food production line, without the need to frequently replace the suction equipment, saving equipment investment and site space.

Customized design

We are well aware that the production needs of different customers are different, so we provide a full range of customized services. From the appearance size, material selection to the internal structure layout of the suction machine, it can be customized according to the customer's actual production site, process requirements and material characteristics. For the clean production environment requirements of some special industries, we can use stainless steel or high-quality materials that meet GMP standards to manufacture suction machines, and equip them with efficient air filtration systems to prevent materials from being contaminated by the outside world and ensure the quality and safety of the products.

Safety and reliability, quality assurance

Multiple safety protections

In order to ensure the personal safety of operators and the stable operation of equipment, the suction machine is equipped with multiple safety protection devices. For example, protective grilles are installed at the suction and discharge ports to prevent the operator's fingers or other foreign objects from accidentally entering the equipment; equipped with pressure sensors and overload protection devices, when the pressure in the pipeline increases abnormally or the motor load is too large, the equipment will automatically shut down and sound an alarm; at the same time, the grounding protection system can also effectively prevent the occurrence of electrical leakage accidents.

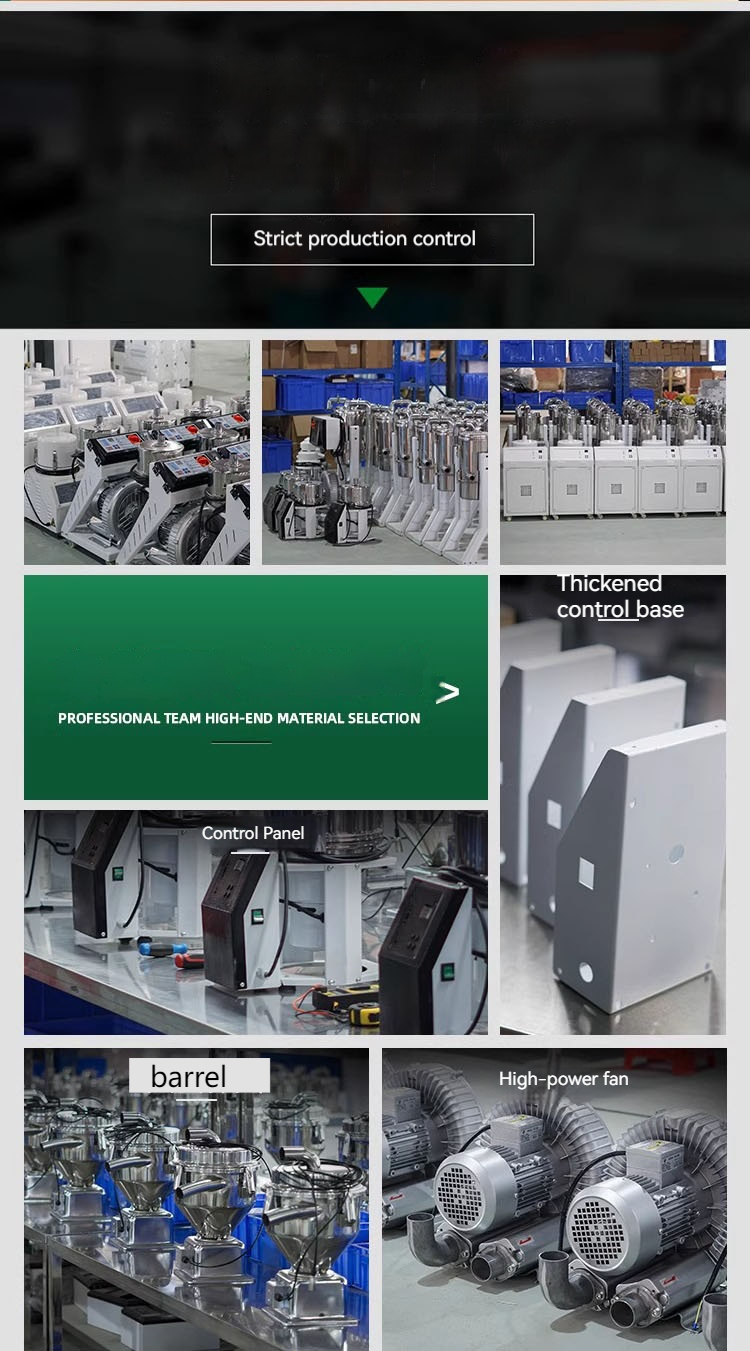

High-quality material selection and exquisite craftsmanship

In the production and manufacturing process, we strictly control the quality of every link. The key components of the suction machine are made of high-quality materials and parts from internationally renowned brands, such as high-performance vacuum pumps, durable seals, precision filters, etc., to ensure the reliability and long life of the equipment. Advanced production technology and strict quality inspection system ensure that every suction machine shipped meets high quality standards, providing customers with stable and reliable material handling solutions.