Masterbatch machines play a pivotal role in the plastic processing industry, enabling precise and efficient incorporation of masterbatches or additives into raw materials. These machines ensure color consistency and high-quality production, meeting the diverse requirements of modern plastic manufacturing.

A masterbatch machine is an advanced device used for accurately metering and incorporating masterbatches—color pigments or additives—into plastic raw materials during processing. By controlling the masterbatch addition with precision, these machines help achieve uniform color and enhance the overall quality of plastic products. This precision ensures consistent results, whether in injection molding, extrusion, or other plastic processing techniques.

The operation of a masterbatch machine relies on a meticulously designed mechanism for feeding and mixing materials. Below is an explanation of the working principle:

Material Feeding: Plastic raw materials enter the main processing equipment through the primary feed inlet. Simultaneously, the masterbatch machine dispenses masterbatch from its hopper at a pre-set ratio.

Conveyance Mechanism: Masterbatch machines use screw conveyors or gear systems to transport masterbatches into the primary material stream. The screw’s rotational speed, driven by an electric motor, determines the amount of masterbatch added. Modern control systems allow precise adjustments to the motor speed, ensuring highly accurate dosage.

Mixing and Integration: As the masterbatch blends with the raw material, the result is a uniform distribution of color or additive properties. This ensures the end product maintains consistent quality and aesthetics.

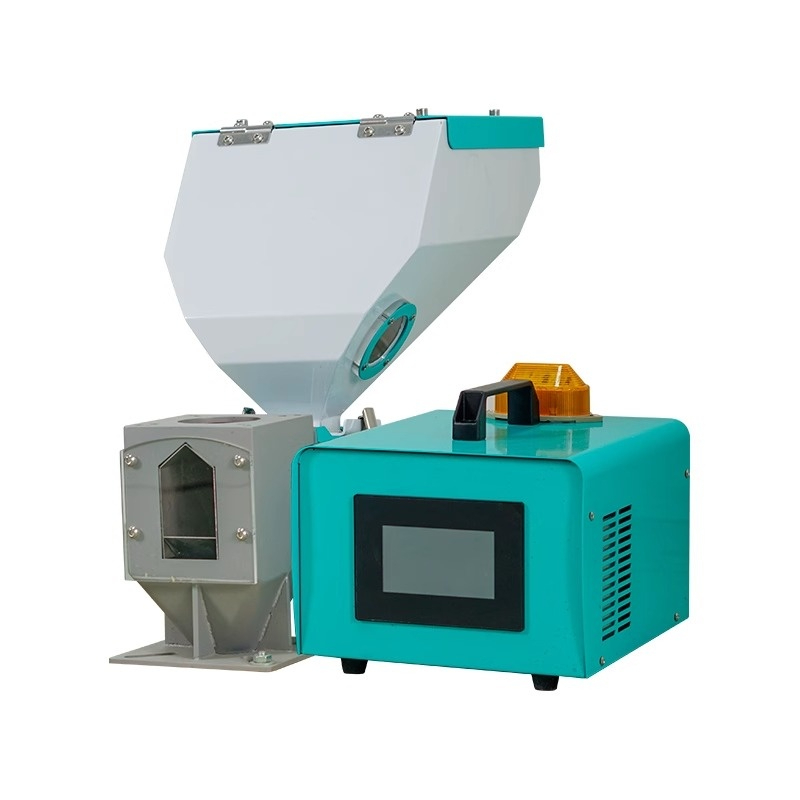

Masterbatch machines are composed of various components, each serving a specific purpose to ensure accurate operation. Below are the primary structural elements:

Hopper:

Stores masterbatch materials before they are dispensed.

Typically made from stainless steel to prevent contamination and ensure durability.

Designed with airtight seals to avoid exposure to external impurities.

Conveyance System:

Screw-based systems use precisely engineered screws with defined pitches and diameters to transport masterbatches. These parameters influence the precision of material dispensing.

Gear-based systems rely on interlocking gears to deliver consistent amounts of masterbatch.

Control System:

The control system serves as the brain of the machine, regulating the masterbatch addition rate.

It can range from simple knob-based controllers to sophisticated touch-screen systems that allow real-time monitoring and parameter adjustment.

Base and Casing:

The base ensures machine stability during operation.

The outer casing protects internal mechanical and electrical components. Typically made of metal, it is treated to resist rust and wear.

Masterbatch machines are highly adaptable and can be integrated into various plastic processing methods, including:

Injection Molding: Ensures precise coloration of molded components.

Extrusion Processes: Maintains consistent color and quality across extruded plastic profiles, films, and sheets.

Blow Molding: Facilitates uniform color distribution in hollow products like bottles.

Masterbatch machines bring numerous benefits to the plastic manufacturing process. Here are some of the most significant advantages:

One of the standout features of masterbatch machines is their ability to accurately control the addition of masterbatches. With a typical error margin as low as ±1%, these machines are critical for applications requiring precise color consistency. This precision reduces material wastage and ensures cost efficiency.

By ensuring even distribution of masterbatches throughout the raw material, these machines eliminate the risk of uneven coloration or additive dispersion. This uniformity enhances the visual appeal and functional properties of plastic products, meeting stringent quality standards.

Masterbatch machines are designed to cater to a wide range of plastic manufacturing needs:

Adjustable masterbatch ratios allow manufacturers to produce products with varying color intensities or additive concentrations.

Advanced models can store multiple ratio presets, enabling quick transitions between production runs with different requirements.

These machines are suitable for processing various thermoplastics and some thermosets, making them indispensable for diverse industries. From packaging materials to automotive components, the compatibility of masterbatch machines spans across numerous applications.

Equipped with intelligent control systems, masterbatch machines simplify operations and enhance productivity. Features like real-time monitoring, automatic adjustments, and error alerts minimize downtime and ensure seamless production workflows.

The use of robust materials like stainless steel for key components ensures the longevity of masterbatch machines. Their design also prioritizes cleanliness, preventing contamination and maintaining product quality.

Masterbatch machines are indispensable for achieving consistent and high-quality plastic products. By providing precision in additive dispensing, uniform mixing, and broad adaptability, they meet the demands of modern manufacturing processes. Whether in injection molding, extrusion, or blow molding, masterbatch machines elevate production efficiency while maintaining stringent quality standards.

For industries focused on producing flawless plastic components, investing in advanced masterbatch machines is a strategic decision that delivers long-term value. With their cutting-edge technology and versatile applications, these machines continue to revolutionize the plastic manufacturing sector.