A slow speed grinder, also known as a slow-speed crusher or low-speed pulverizer, is an advanced piece of equipment designed for precise and efficient material processing. This innovative machinery is widely used across various industries, including plastics, rubber, wood, and fiber processing, thanks to its ability to handle diverse materials and applications. It offers a distinct advantage over traditional high-speed grinders due to its slow rotational mechanism, which ensures stability, precision, and energy efficiency.

One of the key features of a slow speed grinder is its precision-engineered low-speed, high-torque motor. Unlike traditional high-speed grinders that can generate excessive heat, the slow rotation of this system minimizes temperature increases during the grinding process. This is particularly critical for temperature-sensitive materials, as it prevents changes in their properties or degradation. By operating at a stable and controlled speed, the slow-speed grinder ensures the material's integrity throughout the pulverization process.

The slow-speed grinder boasts a multi-layered special crushing disc and a fixed tooth disc that work in tandem. The crushing disc is constructed from high-quality alloy steel and undergoes a specialized heat treatment process, which imparts exceptional hardness and wear resistance. The blade design and arrangement on the disc are optimized to create strong shear forces, extrusion forces, and friction. These forces act on the material, gradually reducing it to the desired particle size, making the equipment ideal for processing hard and soft materials alike.

Flexibility is a hallmark of the slow-speed grinder. To cater to diverse material processing needs, it is equipped with a precise gap adjustment device. This mechanism allows operators to fine-tune the gap between the crushing disc and the fixed tooth disc, enabling them to achieve specific particle size requirements. Whether for coarse crushing or fine grinding, this flexibility ensures the machine meets the unique demands of various industrial processes.

Key Features and Advantages

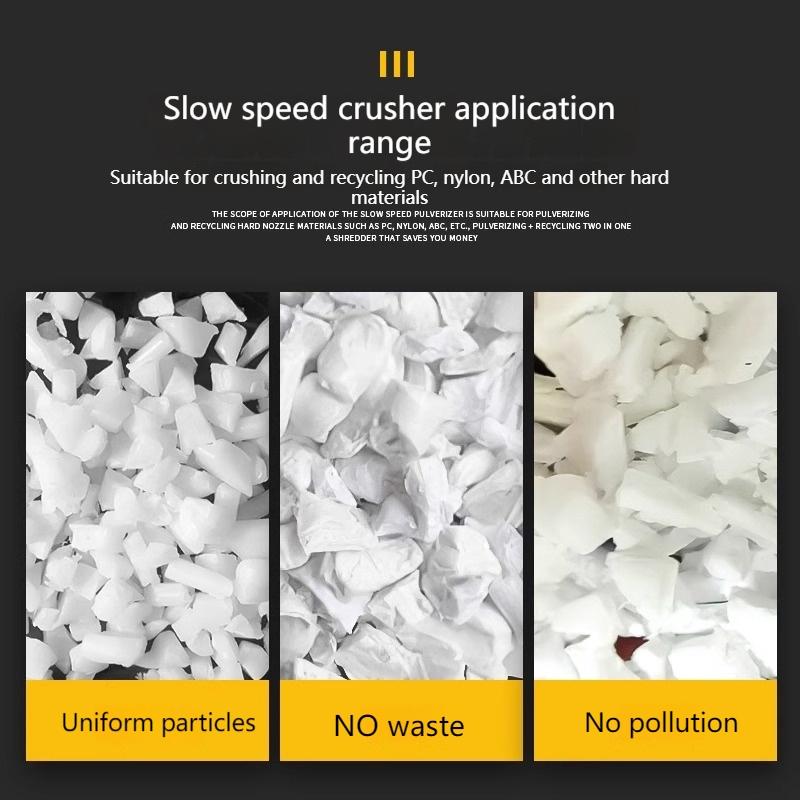

The slow-speed grinder is versatile and can handle an extensive range of materials, from brittle substances like plastics and rubber to tough fibers and even moist materials. Its ability to process raw materials of different shapes—such as blocks, flakes, or strips—without requiring complex pretreatment processes significantly enhances production efficiency.

Traditional high-speed grinders often produce significant noise and vibration, leading to potential operator discomfort and increased equipment wear. In contrast, the slow-speed grinder operates with reduced noise levels and minimal vibration due to its stable and optimized mechanical design. This ensures a quieter working environment and extends the lifespan of the equipment by minimizing part wear and loosening caused by vibrations.

One of the standout features of the slow-speed grinder is its impressive energy utilization efficiency. Compared to high-speed grinding equipment, energy consumption can be reduced by over 30%, depending on the application. Furthermore, the machine's durability and reduced wear mean fewer replacement parts are needed, decreasing material waste and overall maintenance costs. These attributes align with the modern industry's emphasis on sustainable and environmentally friendly practices.

The user-centric design of the slow-speed grinder simplifies operation and maintenance. Its intuitive interface allows operators to easily manage tasks such as starting, stopping, and adjusting parameters. Maintenance is equally straightforward, with quick and simple processes for replacing wear parts like crushing discs and screens. This minimizes downtime and operational disruptions, ensuring consistent productivity.

Applications of Slow Speed Grinders

Slow-speed grinders are indispensable in industries requiring precise material processing. Below are some of the primary applications:

In the plastics industry, slow-speed crushers are often used as injection molding machine side crushers. They efficiently process rejected parts, sprues, and runners into reusable granules, reducing material waste and lowering production costs.

The slow-speed grinder is highly effective in pulverizing wood chips, sawdust, and other biomass materials for applications such as biofuel production and composite material manufacturing. Its ability to maintain material properties during grinding is crucial in these applications.

In industries that handle tough materials like synthetic fibers or rubber, the robust design of the slow-speed grinder ensures efficient size reduction. Its low temperature rise during operation prevents material degradation, making it suitable for high-quality end products.

For temperature-sensitive materials or materials that require fine particle sizes, slow-speed grinders provide unparalleled precision. Their flexible gap adjustment mechanism allows customization to meet specific requirements in industries like pharmaceuticals and food processing.

Choosing the Right Slow Speed Grinder

When selecting a slow-speed grinder, consider the following factors to ensure optimal performance:

1. Material Compatibility: Assess whether the machine can handle the hardness, moisture content, and shape of your materials.

2. Customizability: Ensure the grinder provides adjustable settings to achieve desired particle sizes.

3. Energy Efficiency: Look for machines with proven energy-saving features to reduce operational costs.

4. Durability: Opt for grinders with wear-resistant materials and reliable components to ensure longevity.

5. Noise and Vibration Levels: Choose equipment with low noise and vibration output for a better working environment.

Slow-speed grinders are revolutionizing material processing across industries. Their innovative design, characterized by a slow drive system, powerful crushing structure, and precise adjustment capabilities, ensures efficient, accurate, and stable operations. By offering wide applicability, energy efficiency, and ease of maintenance, these machines cater to the needs of modern industries. Whether used as industrial crushers, injection molding machine side crushers, or slow-speed pulverizers, they provide a comprehensive solution for material size reduction.

With continuous advancements in grinding technology, slow-speed grinders are poised to play an even more significant role in industrial material processing, ensuring efficiency, sustainability, and superior product quality.