Industrial Intelligent Mold Temperature Machine: 12KW/180°C Oil Temperature Machine

Item NO.:

00049Order(MOQ):

1Market Price:

$363Price:

$363Product Origin:

Huizhou, ChinaColor:

WhiteShipping Port:

Shenzhen, ChinaLead Time:

15 Days

Mold Thermostat

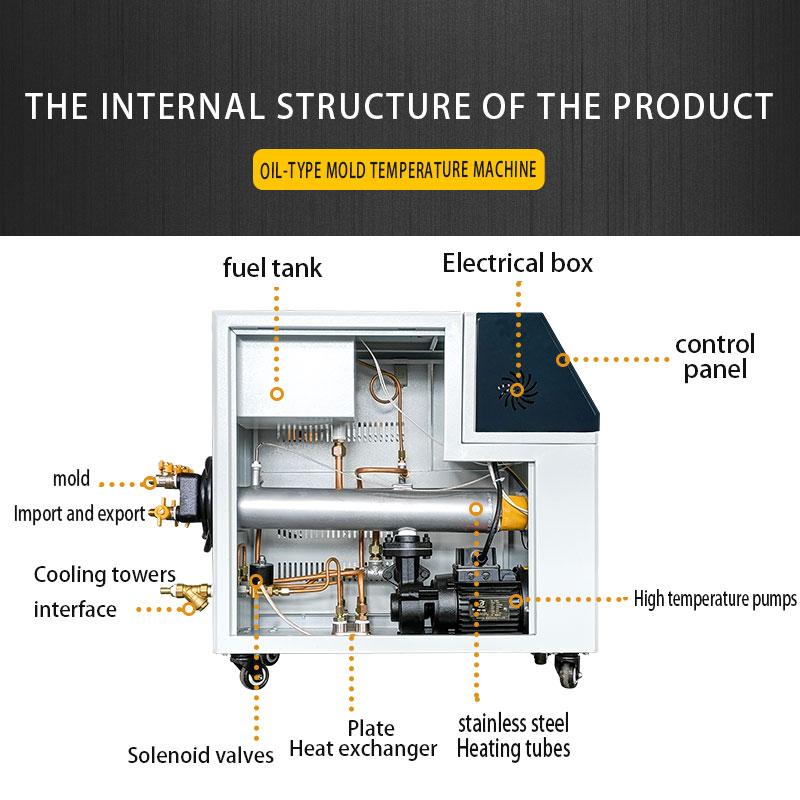

As a kind of precision temperature control equipment, the core function of the mold temperature machine is to be able to accurately adjust the temperature of the mold to ensure the constant temperature environment required in the production process. It consists of several key components, including a heating barrel, a heating and cooling system, a power transmission system, a level control system, as well as a temperature sensor, an injection port, and more.

Key Features:

1. Exclusive Customization:

We will tailor different KW water/oil mold thermostats for you according to the needs of customers, and the price required for different power and water and oil will be different.

2.. Precise temperature control

The mold thermostat adopts advanced temperature monitoring and feedback system, which can realize the precise control of mold temperature, ensure that the mold is in the best temperature environment during the production process, and greatly improve the product quality consistency.

3. Energy efficient

The unique heating and cooling design makes full use of the heat circulation, greatly reduces energy consumption, saves more than 30% of energy consumption compared with traditional methods, and realizes more environmentally friendly and energy-saving production.

4. Easy to operate

The user-friendly control interface design is simple and easy to use, even non-professionals can quickly master the use skills, which greatly improves the applicability and efficiency of the equipment.

5. Stable and reliable

The use of high-quality core components, with intelligent monitoring system, to ensure the long-term stable operation of the equipment, minimize the risk of failure and downtime losses, and create greater value for users.

6. Widely applicable

Whether it is injection molding, die-casting or other thermoforming processes, the mold thermostat is capable of meeting the temperature control needs of different industries and materials, and has strong applicability.