Item NO.:

00062Order(MOQ):

1Market Price:

$642Price:

$642Product Origin:

Huizhou, ChinaColor:

WhiteShipping Port:

Shenzhen, ChinaLead Time:

15 Daysmasterbatch machines

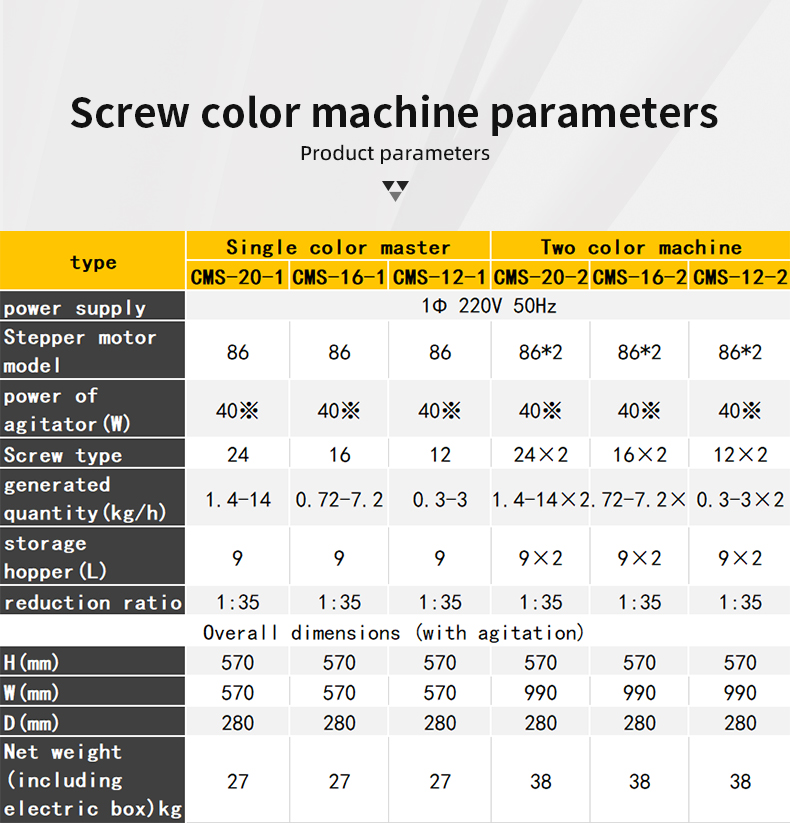

The masterbatch machine is a kind of equipment specially used for coloring plastics, rubber and other materials, by mixing the masterbatch with the substrate, to ensure that the color of the product is uniform and stable. The emergence of masterbatch machine has greatly improved production efficiency and product quality, and is widely used in plastics, packaging, automobiles, electronics and other industries. Its core function is to precisely control the amount of masterbatch added and the uniformity of mixing, so as to achieve plastic products with different colors and effects.

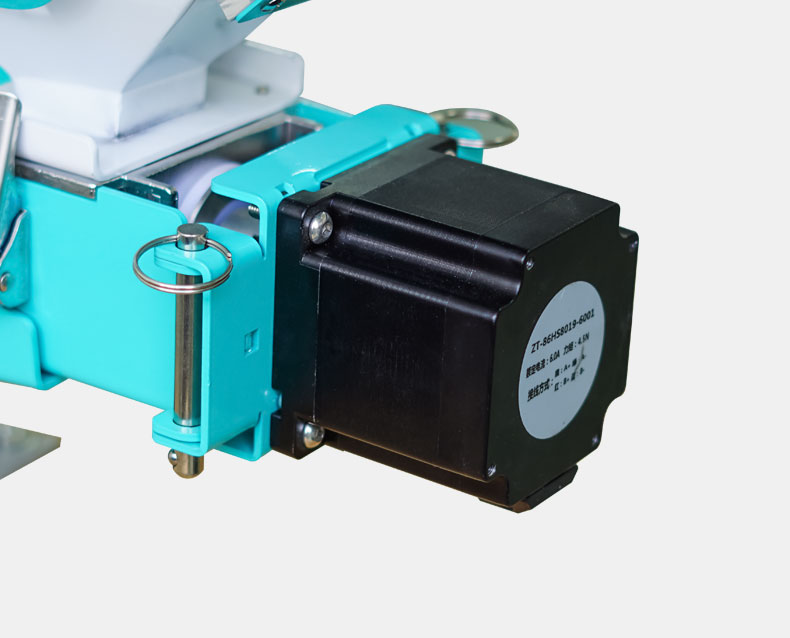

The working principle of the masterbatch machine is relatively simple. The machine melts and mixes the masterbatch with the base plastic at high temperatures through a screw extrusion system. By adjusting parameters such as screw speed, temperature and pressure, precise control of the masterbatch can be achieved, ensuring the color consistency and stability of the final product. Modern masterbatch machines are usually equipped with advanced automation control systems, which are able to monitor the mixing status in real time to ensure the efficiency and stability of the production process.

In addition, the design of the masterbatch machine also pays great attention to energy saving and environmental protection. Many plants use high-efficiency heating systems that reduce energy consumption while ensuring adequate melting of masterbatches. At the same time, the closed design of the masterbatch machine can effectively prevent the leakage of dust and odor, and the impact on the environment is minimized.

In terms of maintenance, the structure of the masterbatch machine is reasonable, easy to clean and maintain. Users can quickly change screws and molds according to different production needs, ensuring the flexibility and adaptability of the equipment. In general, the masterbatch machine is an indispensable and important equipment in the modern plastic processing industry, which can effectively enhance the market competitiveness of products.

Key Features:

1. Efficient mixing performance

Advanced mixing technology is used to ensure that the masterbatch and substrate are fully and evenly mixed, improving the color dispersion effect and meeting strict production standards.

2. Intelligent operating system

Equipped with a user-friendly intelligent control interface, real-time monitoring of mixing status, simplifying the operation process, reducing human error, and improving production efficiency.

3. Durable structure design

It is manufactured with high-quality wear-resistant materials to ensure long-term stable operation of the equipment in a high-intensity working environment, reduce maintenance costs and prolong service life.

4. Energy saving and environmental protection

The design is optimized to reduce energy consumption, reduce material waste in the production process, meet modern environmental standards, and help enterprises achieve sustainable development.

5. Wide adaptability

It can handle many types of plastics and masterbatches, flexibly adapt to the needs of different customers, and is suitable for various industries, such as plastic processing, packaging, etc.