In industrial production, pulverizer is an indispensable and important equipment. Choosing the right pulverizer model directly affects production efficiency and product quality. So, how can you choose the pulverizer that best suits your needs? What are the key factors? Let us tell you one by one.

1.Material characteristics

First, it is necessary to clarify the properties of the material to be crushed, such as hardness, toughness, water content, etc. Different types of crushers are required for materials with different characteristics. For example, for hard and brittle materials, you can choose the medium-speed crusher of Qindao Machinery, which adopts axial sprocket drive and is equipped with an adjustable pneumatic pusher to ensure smoother crushing and increase crushing output; for fibrous materials, you can choose the low-speed crusher of Qindao Machinery, which adopts a reduction motor and a blade matched with SKD material, and can crush both soft and hard materials.For high-humidity materials or materials that are easily deformed, you can choose the slow-speed crusher from Qindao Machinery.

2.Output requirements

It is important to select the appropriate crusher model and specifications according to the actual production capacity requirements of the production line. If the output is too small, it will affect the overall production efficiency; if the output is too large, it will cause the equipment to be overloaded. Therefore, it is necessary to fully evaluate the current and future production scales and select a matching crusher model.

3.Energy consumption index

The crushing process consumes a lot of electricity, so energy consumption index is also an important criterion for selecting a crusher. New energy-saving technologies such as variable frequency speed regulation and high-efficiency motors can effectively reduce operating power consumption and production costs. Under the same production capacity conditions, it is a wise choice to choose a low-energy crusher model under Qindao Machinery.

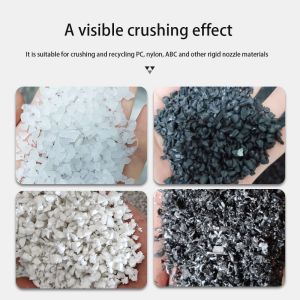

4.Crushing effect

Different application scenarios have different requirements for the particle size distribution of the crushed product. Some require ultra-fineness, while others require coarser. Therefore, when selecting a model, you must fully understand the specific requirements of the final product for the crushed particle size and choose a crusher that can achieve the desired particle size.

5.Maintenance cost

In addition to the initial investment, the long-term maintenance cost of the crusher is also an important indicator. Choosing Qindao Machinery brand products with reliable quality and easy-to-obtain spare parts can greatly reduce the subsequent maintenance costs. At the same time, choosing a crusher model with a high degree of automation and easy operation can also help reduce manual maintenance costs.

In short, choosing the right crusher model requires comprehensive consideration of factors such as material characteristics, output requirements, energy consumption indicators, crushing effect, maintenance costs, and speed requirements. Only by adapting to local conditions can we ensure that the crushing equipment can perform at its best and create the greatest value for the production line. As a senior supplier in the industry, Qindao Machinery has rich experience in crusher selection, and welcomes inquiries from friends from all walks of life.